Description

ALUMINUM ANODES

ALUMINUM ANODES

Aluminum anodes are an economical choice for corrosion

protection in saltwater environments, where electrical resistivity is usually low. They generally consume slower than

magnesium or zinc anodes in the same environment, thereby

providing a longer active life.

Specification

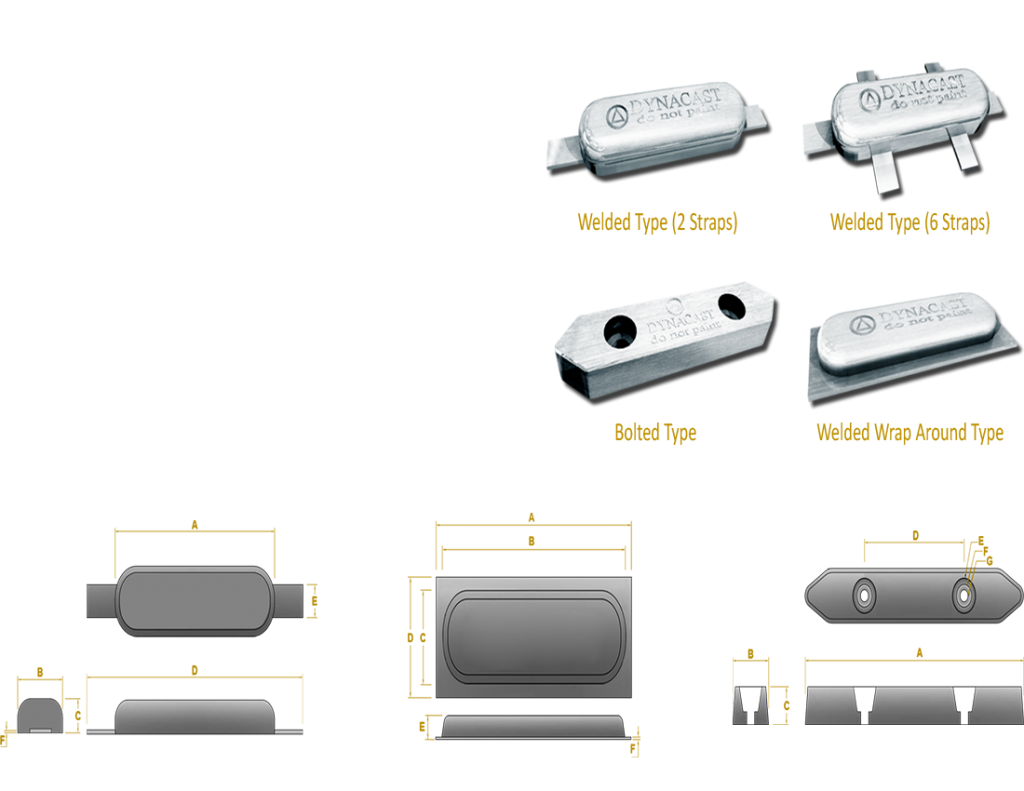

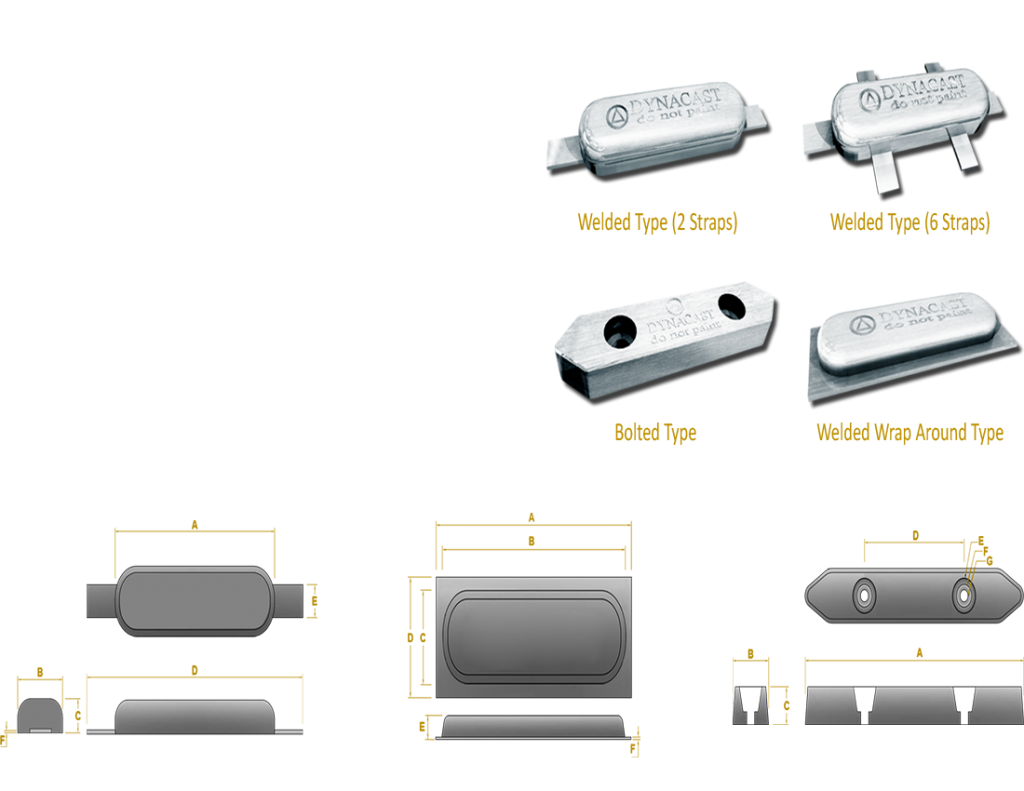

Welded Type Anodes

| Type |

A |

B |

C |

D |

E |

F |

G |

H |

WEIGHT kg |

| 2 kls. (2 straps) |

170 |

107 |

40 |

285 |

47 |

8 |

|

|

2 |

| 4 kls. (2 Straps) |

300 |

110 |

37 |

410 |

47 |

8 |

|

|

4 |

| 4.8 kls. (2 Straps) |

380 |

110 |

58 |

500 |

47 |

8 |

|

|

4.8 |

| 5.4 kls. (2 Straps) |

380 |

110 |

58 |

500 |

47 |

8 |

|

|

5.4 |

Bolted Type Anodes

| Type |

A |

B |

C |

D |

E |

F |

G |

H |

WEIGHT kg |

| 1.2 kls. (Hexagon) |

245 |

95 |

40 |

105 |

36 |

32 |

18 |

|

1.2 |

| 4.8 kls. (Hexagon) |

320 |

107 |

49 |

165 |

50 |

33 |

20 |

|

4.8 |

| 5.5 kls. (Hexagon) |

500 |

83 |

57 |

230 |

50 |

33 |

20 |

|

5.5 |

Welded Wrap Around Type Anodes

| Type |

A |

B |

C |

D |

E |

F |

G |

H |

WEIGHT kg |

| 4.5 kls. |

350 |

305 |

113 |

150 |

35 |

6 |

|

|

4.5 |

| 6.5 kls. |

400 |

275 |

125 |

150 |

35 |

6 |

|

|

6.5 |